S

Description

Basic Info.

| Model NO. | Nova-220127A |

| Design | High Flextion 145 |

| After-Sale Service | Onsite Training |

| Material | Co-Cr-Mo/UHMWPE |

| Product Name | Artificial Hip Joint |

| Properties | Implant Materials & Artificial Organs |

| Transport Package | Standard Export Carton |

| Specification | Nova-220127 |

| Trademark | OEM/Novaluck |

| Origin | China |

| HS Code | 9018390000 |

| Production Capacity | 2000 PC/Month |

Product Description

Product DescriptionS-ROM Titanium alloy cementless hip joints for revision arthroplasty surgery

1. Product Name: ML-TH High quality Ti-alloy cementless femoral stem

2. Certificate:ISO,CE

3. Material: Ti Alloy

4. AK-ML-TH Features :

Proximal Coating: Titanium Plasma Spray + HA Coating;

Tapered Wedge design provides firm mediolateral stability within the femoral canal;

Both 127 and 132 of Neck Shaft Angle are available;

24 sizes full length stem available in full profile and reduced distal options;

Polished Anterior-Posterior Neck Flats increase ROM by geometrically reducing the potential for impingement of the neck with the cup;

Flat Tapered Wedge Geometry Enhances proximal offloading and bone preservation and provides for rotational stability;

Reduced Distal Transition Enhances implant fit in femoral canals with a proximal/distal mismatch.

3D ACT series products achieve the innovative breakthrough in personalized medical solutions, the world's first series products that get the clinical approval to sell in market.

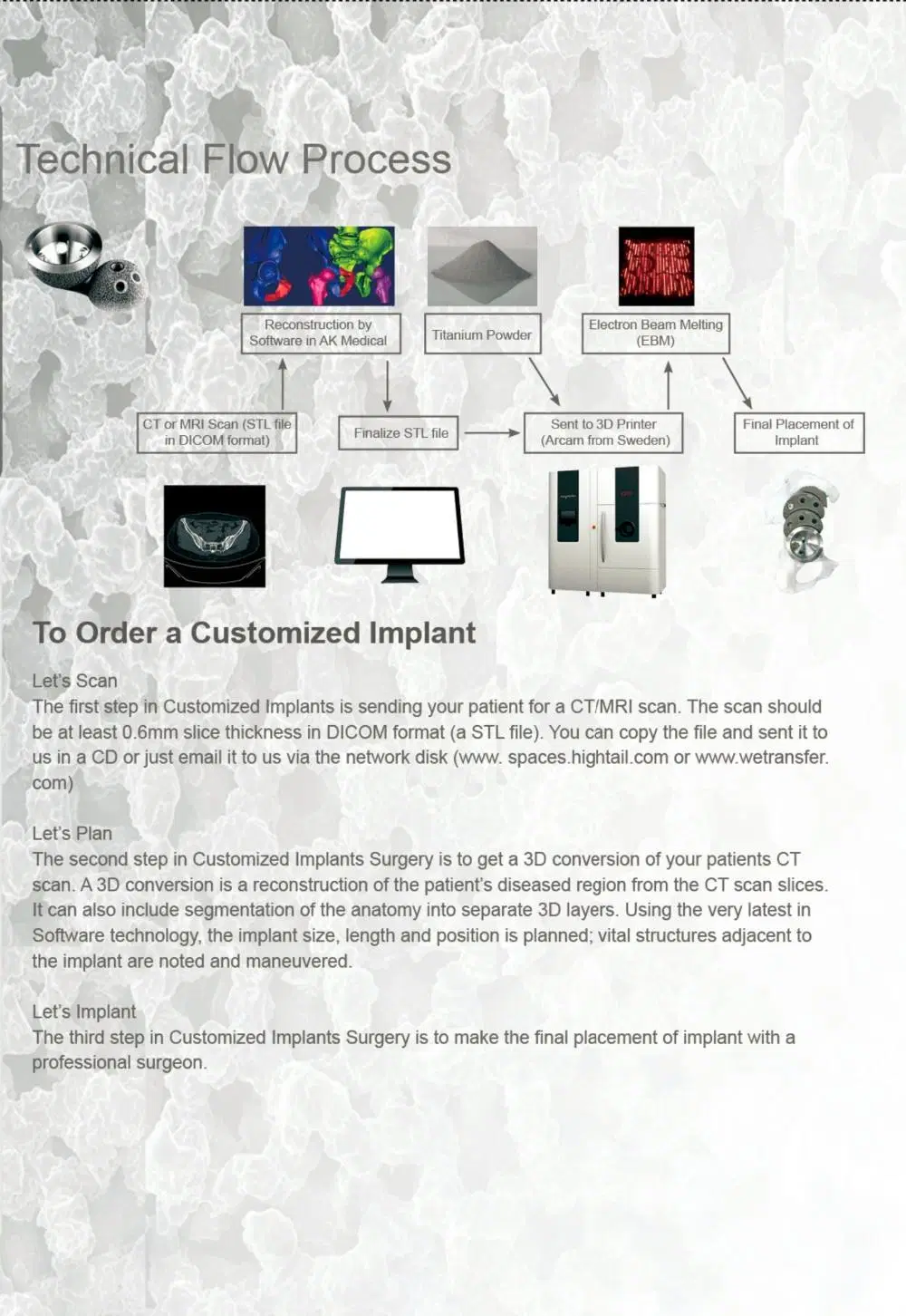

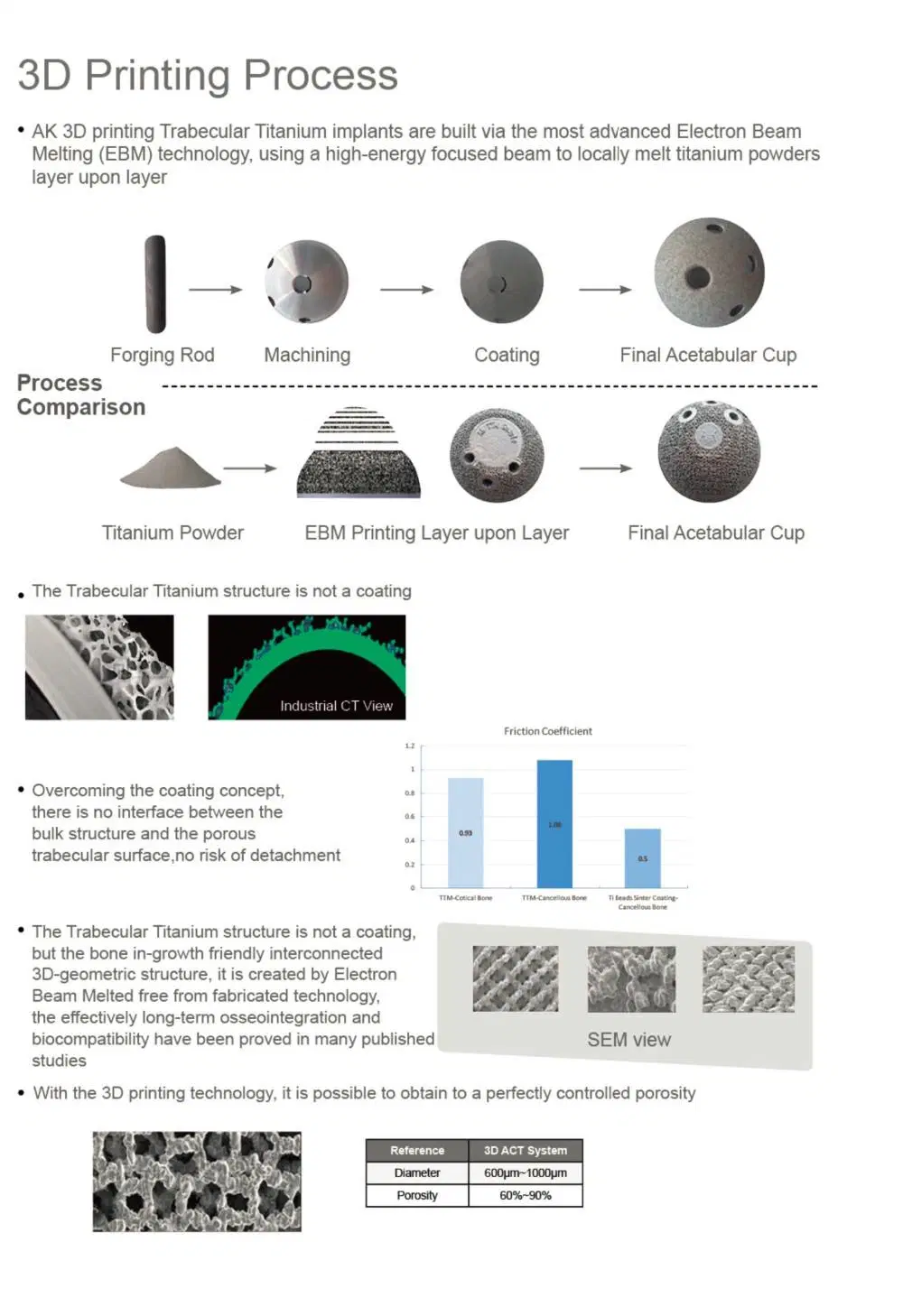

The prosthetic components in Trabecular Titanium are built via the most advanced Electron Beam Melting (EBM) technology, using a high-energy focused beam to locally melt metallic powders layer upon layer in a one-step manufacturing process, which can help to get the structure which traditional process can not realize. Overcoming the coating concept, there is no interface between the bulk structure and the porous trabecular surface.

With the 3D printing technology, it is possible to obtain titanium components without coatings thanks to a perfectly controlled porosity.

The regular, three-dimensional, hexagonal cell structure imitates trabecular bone morphology; it has a high open porosity (80%) and a mean pore diameter of 800 μm. High open porosity and adequate pore size are expected to enhance cell migration and vascularization, facilitating the transport of oxygen, nutrients, ions and bone inducing factors, favoring new bone formation.

F

at

ures

| Q1. Is free sample available? |

| A: Yes, sure. we are happy to send free samples of some items for quality evaluation first. Please feel free to contact us. |

| Q2. What is your lead time? |

| A: Normally 3-7 days in general |

| Q3. How does your factory do regarding quality control? |

| A: Quality is priority. All raw material we used are non-toxic, environmental-friendly. We have a professional QA/QC team to ensure the quality. And all pass the test report. |

| Q4. Do you accept OEM or ODM order? |

| A: Yes, sure. we accept both OEM and ODM for customers. |

| Q5. What are your terms of delivery? |

| A: We can accept EXW, FOB, CIF, etc. depends on which one you prefer. |

| Q6. What is the payment way? |

| A: TT, westeruion, ect. |

Prev: Medical Implants Stainless Titanium Four Axis Knee Joint

Next: Titanium Alloy Metal Femoral Stem Artificial Hip Joint Made in China

Our Contact